Efficiency

Gains.

As equipment wears and ages, inefficiencies start to appear through lowered throughput and performance. We can step in by providing predictive maintenance and monitoring solutions.

What we

provide.

As time passes by, process discrepancies tend to bare their teeth through plant inefficiencies and equipment degradation. This can inhibit your plant from reaching its full potential, resulting in declining efficiency and less throughput where it once existed.

Keeping things running at

their best.

Diagnostics

As electromechanical components begin to degrade, this heightens inefficiencies seen in production from throughput to faster wear and tear on associated hardware. We offer a diagnosis service to help predict and evaluate inefficiencies on rotational hardware using vibration analysis tools to monitor levels over time.

Maintenance

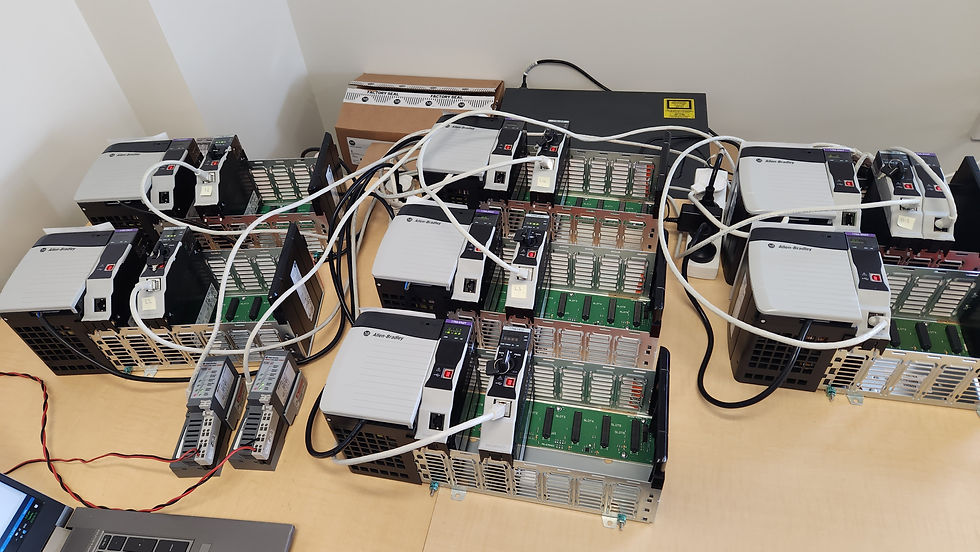

As a result of intuition and our diagnosis services, we can perform replacement and maintenance services to help reduce inefficiency in your process. With skills in servicing and upgrading hardware, we can get your plant back on track to performing at its peak.

Optimisation

There are often opportunities to improve a process starting with the components used and the code behind them. From exchanging sensor types to optimising programs, we can evaluate and alter your process to boost reliability and stability. With modern visualisation techniques, we can also put in perspective OEE information to keep you in the loop with your process like never before.

Want to learn more?

Contact us below and we'll be in touch.